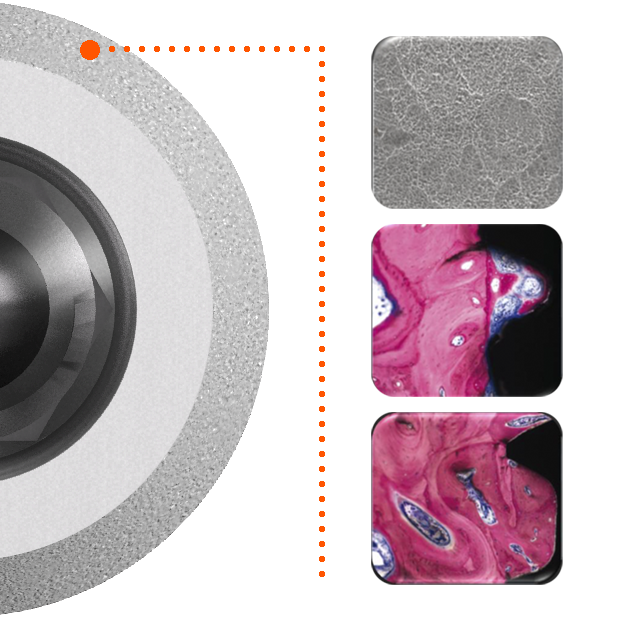

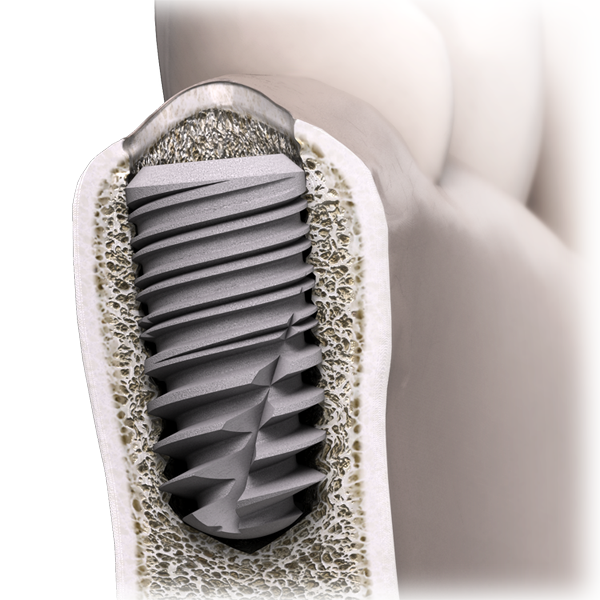

The In-Kone® implant is a bone level type of implant. However, with respect to biological status, the positioning of the implant shoulder was revised so that the roughened chamfer could be sited under the cortical bone.

The aim of this positioning was to remove all constraints from the bony crest and recreate a favourable environment for setting the implant(1). The peri-implant bone plates support the mucosa and contribute to the aesthetic rendering of restorations.

With the In-Kone® system, this surgical technique is combined with use of “tulip” prosthetic components which are designed to reduce the route of entry for potentially undesirable bacteria and thicken the mucosal divisions(2).